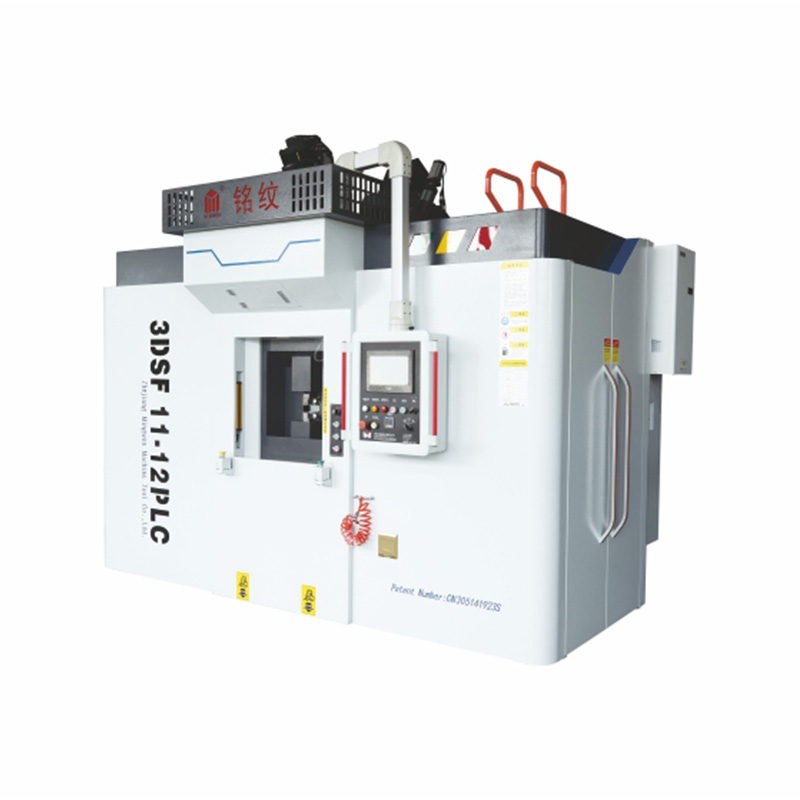

3DSF15-15CNC Rotary Transfer Machine For Malleable Steel Joints

The 3DSF15-15CNC Rotary Transfer Machine for Malleable Steel Joints represents a solution for precision machining in the production of malleable steel joints. This specialized machine offers a range of features designed to enhance efficiency, accuracy, and reliability in the manufacturing process.

Versatile Processing Options

One standout feature of this rotary transfer machine is its versatility in processing various types of malleable steel joints. The 3DSF15-15CNC is designed to accommodate a wide range of joint sizes and shapes, making it a versatile solution for manufacturers with diverse production needs. This adaptability allows for increased flexibility in manufacturing processes, enabling the machine to handle different joint configurations efficiently.

High Production Efficiency

With its automated features and streamlined operation, the machine significantly reduces the time required for the production of malleable steel joints. This efficiency not only enhances overall productivity but also contributes to cost-effectiveness in large-scale manufacturing operations.

Robust Construction for Longevity

Durability is a key consideration in the design of the 3DSF15-15CNC, ensuring a robust and reliable performance over an extended operational lifespan. The machine is constructed with high-quality materials and components, capable of withstanding the rigors of continuous use in industrial settings. This robust construction contributes to reduced maintenance requirements and increased uptime, resulting in a more dependable manufacturing solution.

Integrated Cooling System

To ensure good performance during prolonged machining operations, the 3DSF15-15CNC incorporates an integrated cooling system. This system effectively dissipates heat generated during the machining process, preventing overheating and maintaining consistent performance. The cooling system contributes to the longevity of the machine and the quality of the finished malleable steel joints.

Energy-Efficient Operation

With a focus on sustainability and energy efficiency, the 3DSF15-15CNC is designed to operate with minimal energy consumption. The machine incorporates advanced energy-saving features without compromising on performance, making it an environmentally conscious choice for manufacturers seeking to reduce their carbon footprint. This energy-efficient operation aligns with modern industry standards and reflects a commitment to responsible manufacturing practices.

Customizable Tooling Options

Recognizing the diversity of malleable steel joint applications, the 3DSF15-15CNC offers customizable tooling options. This allows manufacturers to tailor the machining process to specific joint requirements, optimizing the efficiency and precision of the machine for different applications. The ability to customize tooling enhances the machine's adaptability and ensures it can meet the unique needs of various production scenarios.

Compliance with Industry Standards

The 3DSF15-15CNC is designed and manufactured in compliance with relevant industry standards and regulations. This commitment to quality and adherence to established standards ensures that the finished malleable steel joints meet or exceed industry requirements for performance, safety, and reliability. Manufacturers can rely on the 3DSF15-15CNC to consistently produce joints that meet the high industry standards.

In conclusion, the 3DSF15-15CNC Rotary Transfer Machine for Malleable Steel Joints stands as a reliable and efficient solution for precision machining in the production of malleable steel joints. With its advanced features, versatility, and commitment to quality, this machine offers manufacturers a dependable tool to enhance their manufacturing processes and produce high-quality malleable steel joints for a diverse range of applications.

About

Zhejiang Mingwen Intelligent Technology Co., Ltd.

Zhejiang Mingwen Intelligent Technology Co., Ltd. is a 3DSF15-15CNC Rotary Transfer Machine For Malleable Steel Joints company and wholesale 3DSF15-15CNC Rotary Transfer Machine For Malleable Steel Joints supplier specializing in the manufacture of special waterwheel valve machines.

The company specializes in designing and manufacturing a series of products such as waterwheel type, horizontal type, vertical type, turntable type linkage, and special gate valve sealing surface machines. At the same time, it can customize special machine tools, automated assembly lines, etc. according to user needs. "High precision, strong rigidity, low noise, durability, speed and efficiency" are the characteristics of Mingwen machine tool products.

News

-

In machining environments where high consistency and stable output are essential, hydraulic systems play a critical role in delivering smoot...

READ MORE -

Modern machining environments depend heavily on the consistent performance of hydraulic systems, especially when operating multi-station aut...

READ MORE -

A Rotary Transfer Machine Hydraulic is a robust production asset, yet its complex hydraulic system can develop issues that disrupt manufactu...

READ MORE -

Balancing Advanced Capabilities with Operational Accessibility The value of an automated system is fully realized only when it can be operat...

READ MORE

русский

русский Español

Español