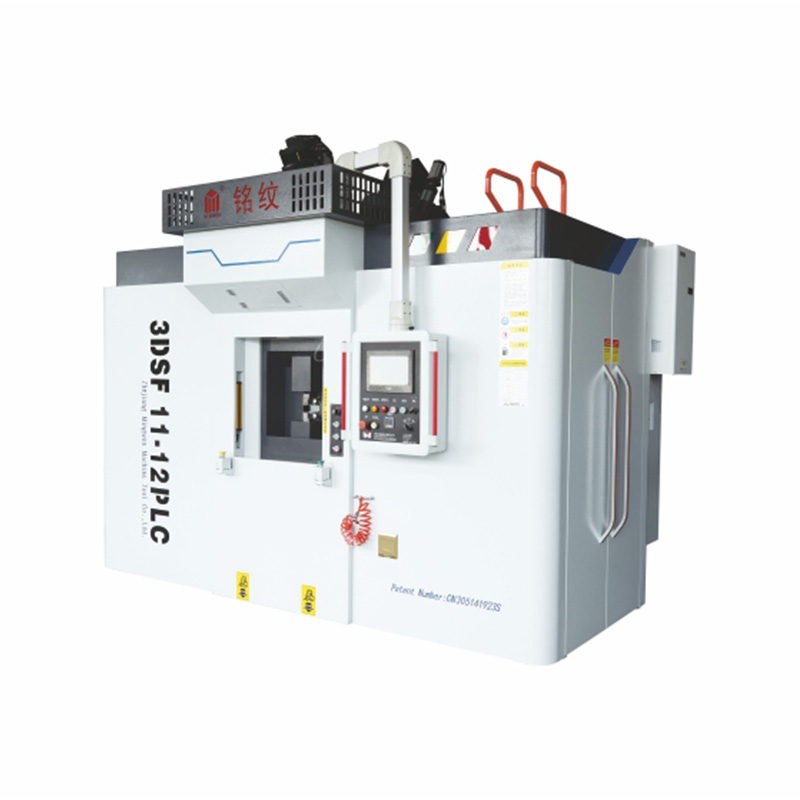

3DSF11-12PLC Rotary Transfer Machine For Self Closing Valve

The 3DSF11-12PLC Rotary Transfer Machine for Self-Closing Valve represents a solution for precision manufacturing in the valve industry. This innovative machine boasts a range of features that set it apart in terms of efficiency, versatility, and reliability.

Product Overview:

Automated Loading and Unloading:

The 3DSF11-12PLC Rotary Transfer Machine is equipped with advanced automation features, facilitating seamless loading and unloading processes. The integration of servo motors ensures precise and efficient handling of materials, contributing to increased productivity and reduced manual labor requirements.

Multi-Spindle Capability:

With its multi-spindle design, this Rotary Transfer Machine accommodates multiple tools simultaneously, enabling the simultaneous processing of multiple components. This not only enhances overall efficiency but also allows for a significant reduction in cycle times.

Specialized for Self-Closing Valves:

The machine is specifically designed for the production of self-closing valves. Its versatility is highlighted by different configurations catering to varying valve specifications, including Eight Station Ten Axis and Eight Station Seventeen Axis variants. The use of materials such as Die Cast Aluminum, Red Punching Aluminum, and Red Punching Copper further emphasizes its adaptability.

Die Cast Aluminum Construction:

The 3DSF11-12PLC Rotary Transfer Machine features a robust construction using Die Cast Aluminum. This material not only ensures durability but also contributes to the overall stability of the machine during operation. The choice of materials reflects a commitment to quality and longevity in the manufacturing process.

Precision in Processing:

Achieving high levels of precision is a hallmark of this Rotary Transfer Machine. The integration of advanced technology allows for accurate machining and shaping of components, meeting the stringent requirements of self-closing valve manufacturing. This precision contributes to the consistent quality of the final products.

Versatility in Material Handling:

The machine's adaptability extends to the variety of materials it can process. From Die Cast Aluminum to Red Punching Aluminum and Red Punching Copper, the Rotary Transfer Machine handles different materials with ease. This versatility ensures that manufacturers can choose the suitable material for their specific application requirements.

Solenoid Valve Processing:

In addition to its specialization in self-closing valves, the Rotary Transfer Machine is also designed for the processing of solenoid valves. This expands its utility, allowing manufacturers to diversify their production capabilities without the need for separate machinery.

Advantages of the 3DSF11-12PLC Rotary Transfer Machine:

Increased Productivity:

The combination of automated features, multi-spindle capability, and efficient material handling contribute to a significant boost in overall productivity. Manufacturers can achieve higher output with reduced cycle times, and their production capacity.

Cost-Efficiency:

The machine's automation not only increases productivity but also leads to cost savings by minimizing the need for manual labor. The efficient use of materials further contributes to cost-effectiveness in the manufacturing process.

Reliability and Durability:

The robust construction of the Rotary Transfer Machine ensures long-term reliability and durability. It is designed to withstand the rigors of continuous operation, providing manufacturers with a stable and dependable machining solution.

Adaptability to Varied Specifications:

The machine's ability to handle different materials and configurations makes it adaptable to a wide range of valve manufacturing specifications. This adaptability is crucial for manufacturers dealing with diverse product lines.

In summary, the 3DSF11-12PLC Rotary Transfer Machine For Self-Closing Valve stands as a testament to precision engineering and technological innovation. Its automated loading and unloading capabilities, multi-spindle functionality, and compatibility with various valve types and materials position it as a versatile and efficient solution for manufacturers in the valve industry.

About

Zhejiang Mingwen Intelligent Technology Co., Ltd.

Zhejiang Mingwen Intelligent Technology Co., Ltd. is a 3DSF11-12PLC Rotary Transfer Machine For Self Closing Valve company and wholesale 3DSF11-12PLC Rotary Transfer Machine For Self Closing Valve supplier specializing in the manufacture of special waterwheel valve machines.

The company specializes in designing and manufacturing a series of products such as waterwheel type, horizontal type, vertical type, turntable type linkage, and special gate valve sealing surface machines. At the same time, it can customize special machine tools, automated assembly lines, etc. according to user needs. "High precision, strong rigidity, low noise, durability, speed and efficiency" are the characteristics of Mingwen machine tool products.

News

-

Aggregate Machine Hydraulic systems are essential in multi-station material processing operations, where precise coordination between multip...

READ MORE -

Aggregate Machine Hydraulic systems play a critical role in ensuring reliable and efficient operation in material handling and processing fa...

READ MORE -

Stable hydraulic pressure is crucial for achieving consistent performance in automated machining equipment. Many manufacturing environments ...

READ MORE -

Routine maintenance plays a major role in preserving the performance and reliability of any hydraulic machining system. This is especially t...

READ MORE

русский

русский Español

Español