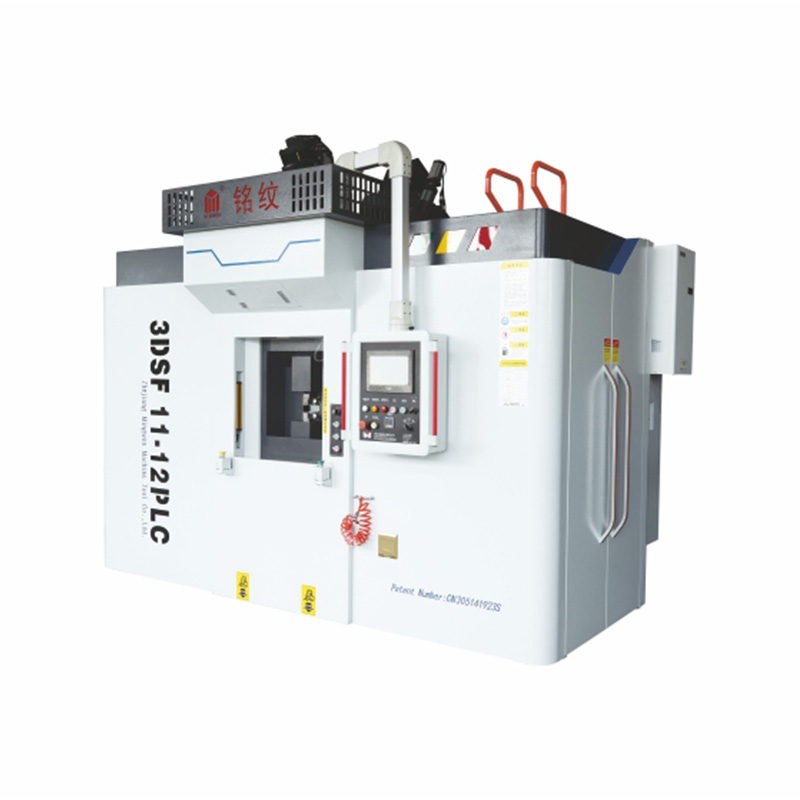

3DSF11-12PLC Rotary Transfer Machine For Water Nozzle Machining

The 3DSF11-12PLC Rotary Transfer Machine for Water Nozzle stands as a testament to precision engineering and advanced automation in the field of metal processing. This device seamlessly integrates a range of features designed to enhance efficiency, accuracy, and flexibility in the production of water nozzles.

Finshed Product of Processing:

One of the key highlights of the 3DSF11-12PLC Rotary Transfer Machine is its ability to consistently deliver high-quality finished products. The machine streamlines the processing of water nozzles, ensuring precision and accuracy at every stage. The finished products exhibit good quality and meet stringent industry standards, making it an solution for manufacturers seeking reliability in their production processes.

Automatic Loading/Unloading:

The inclusion of an automatic loading/unloading system sets the 3DSF11-12PLC apart in terms of efficiency and productivity. This feature effectively reduces manual intervention, reducing downtime and labor costs. The machine's robotic loading and unloading capabilities contribute to a smoother workflow, allowing manufacturers to optimize their production cycles.

Coolant System:

The coolant system of the 3DSF11-12PLC is a testament to its commitment to maintaining operating conditions. Through water cooling, spray, air injection, and other innovative cooling methods, the machine ensures that temperatures remain within the desired range throughout the processing cycle. This not only prolongs the life of the machine components but also contributes to the overall quality of the finished products.

Driving Units/Spindles:

A notable feature of the 3DSF11-12PLC is its flexibility in accommodating various product needs through customized driving units and spindles. The adaptability of the machine allows manufacturers to tailor the processing parameters to the specific requirements of different water nozzle designs. This customization capability enhances the versatility of the machine, making it suitable for a wide range of applications within the metal processing industry.

Precision Engineering:

The 3DSF11-12PLC Rotary Transfer Machine is built on a foundation of precision engineering. From the design phase to the manufacturing process, every element is meticulously crafted to ensure accuracy and consistency. This commitment to precision translates into the machine's ability to produce water nozzles with tight tolerances, meeting the exact specifications demanded by various industries.

Durability and Reliability:

Built with durability in mind, the 3DSF11-12PLC Rotary Transfer Machine is constructed from high-quality materials that withstand the rigors of continuous operation. The robust design ensures longevity, minimizing maintenance requirements and downtime. This reliability is a key factor for manufacturers looking to invest in equipment that delivers consistent performance over an extended period.

Energy Efficiency:

In an era where energy conservation is a priority, the 3DSF11-12PLC stands out for its energy-efficient design. The machine incorporates advanced technologies to optimize power consumption without compromising on performance. This eco-friendly approach aligns with industry trends and regulations, making the machine a responsible choice for environmentally conscious manufacturers.

The 3DSF11-12PLC Rotary Transfer Machine for Water Nozzle represents a significant advancement in the realm of metal processing. With its focus on precision, automation, and adaptability, this machine caters to the evolving needs of manufacturers in diverse industries. As manufacturers seek innovative solutions to enhance their capabilities, the 3DSF11-12PLC stands as a reliable and forward-thinking choice in the landscape of rotary transfer machines.

About

Zhejiang Mingwen Intelligent Technology Co., Ltd.

Zhejiang Mingwen Intelligent Technology Co., Ltd. is a 3DSF11-12PLC Rotary Transfer Machine For Water Nozzle Machining company and wholesale 3DSF11-12PLC Rotary Transfer Machine For Water Nozzle Machining supplier specializing in the manufacture of special waterwheel valve machines.

The company specializes in designing and manufacturing a series of products such as waterwheel type, horizontal type, vertical type, turntable type linkage, and special gate valve sealing surface machines. At the same time, it can customize special machine tools, automated assembly lines, etc. according to user needs. "High precision, strong rigidity, low noise, durability, speed and efficiency" are the characteristics of Mingwen machine tool products.

News

-

In machining environments where high consistency and stable output are essential, hydraulic systems play a critical role in delivering smoot...

READ MORE -

Modern machining environments depend heavily on the consistent performance of hydraulic systems, especially when operating multi-station aut...

READ MORE -

A Rotary Transfer Machine Hydraulic is a robust production asset, yet its complex hydraulic system can develop issues that disrupt manufactu...

READ MORE -

Balancing Advanced Capabilities with Operational Accessibility The value of an automated system is fully realized only when it can be operat...

READ MORE

русский

русский Español

Español