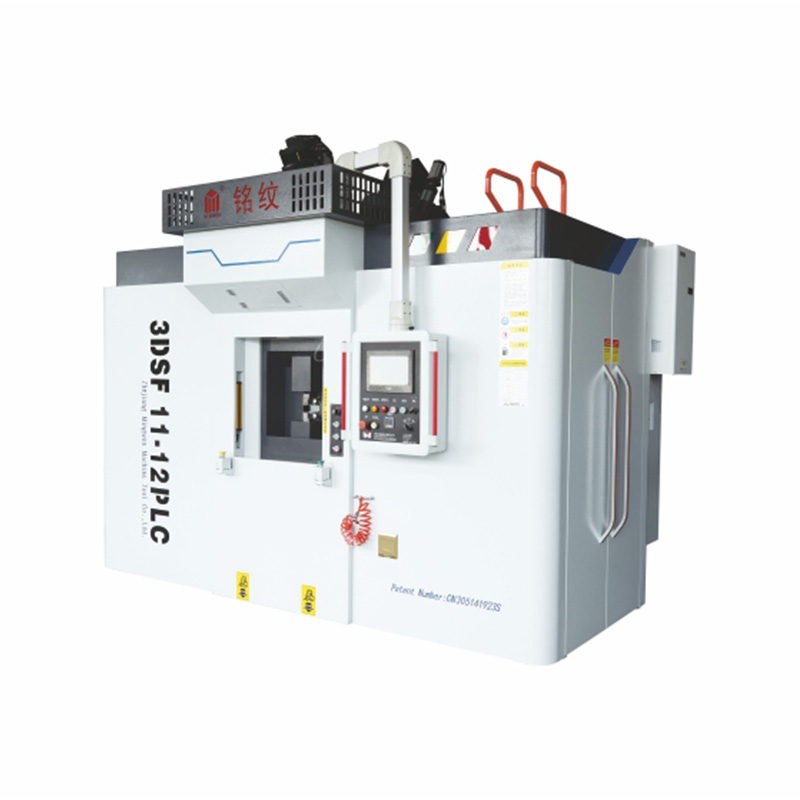

3DSF11-12CNC Rotary Transfer Machine For Joint

In the dynamic landscape of industrial machinery, the 3DSF11-12CNC Rotary Transfer Machine for Joint stands out as a reliable and efficient solution for iron casting union processing. Developed to meet the demanding requirements of modern manufacturing, this machine combines precision engineering with robust construction to deliver good results in joint production.

Efficiency and Speed:

At the core of the 3DSF11-12CNC is its remarkable capability to execute a one-time finish for iron casting unions. This means that the machining process is completed in a single operation, eliminating the need for multiple passes and significantly reducing production time. The machine's high efficiency is a result of its advanced design and engineering, ensuring a swift and accurate processing of each component.

Flexibility and Convenience in Operation:

The operation control system of the Rotary Transfer Machine is characterized by its flexibility and convenience. Operators have the ability to easily navigate and control the machine, allowing for a seamless integration into various manufacturing workflows. The user-friendly interface enhances the overall operational experience, promoting efficiency and reducing the learning curve for operators.

Simultaneous Three-Direction Processing:

One of the standout features of this Rotary Transfer Machine is its unique functional power heads, each capable of simultaneously completing boring and tapping processes in three directions. This multi-directional capability adds a layer of versatility to the machining process, accommodating a wide range of product specifications. The machine adheres strictly to customer product drawing processing standard requirements, ensuring precision and consistency in the finished products.

Customization According to Customer Products:

Recognizing the diverse needs of manufacturers, the 3DSF11-12CNC is designed to be customized according to customer products. This level of adaptability allows the machine to cater to the specific requirements of different industries and applications. Whether it's adjusting the machining parameters or fine-tuning the operation control, the machine can be tailored to meet the unique demands of each production run.

Precision in Processing:

The Rotary Transfer Machine excels in providing a level of precision that is essential in the manufacturing of iron casting unions. The machining process adheres rigorously to customer product drawing processing standards, ensuring that each component meets the specified tolerances and dimensions. This commitment to precision translates to a high-quality finished product that meets or exceeds industry standards.

Reliability and Durability:

Built with durability in mind, the 3DSF11-12CNC is constructed from robust materials and components. This not only enhances the machine's overall lifespan but also contributes to its reliability in demanding manufacturing environments. The machine is engineered to withstand the rigors of continuous operation, making it a dependable asset for manufacturers with high-volume production requirements.

Advanced Cooling Systems

Maintaining right temperatures during processing is crucial for achieving consistent results. The 3DSF11-12CNC Rotary Transfer Machine incorporates advanced cooling systems that effectively dissipate heat, ensuring stable performance throughout extended production runs. This feature is particularly beneficial for manufacturers dealing with high-volume production requirements.

In summary, the 3DSF11-12CNC Rotary Transfer Machine for Joint represents a pragmatic and effective solution for the processing of iron casting unions. With its emphasis on one-time finish, high efficiency, fast processing speeds, and customization options, this machine is well-positioned to meet the evolving needs of modern manufacturing.

About

Zhejiang Mingwen Intelligent Technology Co., Ltd.

Zhejiang Mingwen Intelligent Technology Co., Ltd. is a 3DSF11-12CNC Rotary Transfer Machine For Joint company and wholesale 3DSF11-12CNC Rotary Transfer Machine For Joint supplier specializing in the manufacture of special waterwheel valve machines.

The company specializes in designing and manufacturing a series of products such as waterwheel type, horizontal type, vertical type, turntable type linkage, and special gate valve sealing surface machines. At the same time, it can customize special machine tools, automated assembly lines, etc. according to user needs. "High precision, strong rigidity, low noise, durability, speed and efficiency" are the characteristics of Mingwen machine tool products.

News

-

In machining environments where high consistency and stable output are essential, hydraulic systems play a critical role in delivering smoot...

READ MORE -

Modern machining environments depend heavily on the consistent performance of hydraulic systems, especially when operating multi-station aut...

READ MORE -

A Rotary Transfer Machine Hydraulic is a robust production asset, yet its complex hydraulic system can develop issues that disrupt manufactu...

READ MORE -

Balancing Advanced Capabilities with Operational Accessibility The value of an automated system is fully realized only when it can be operat...

READ MORE

русский

русский Español

Español