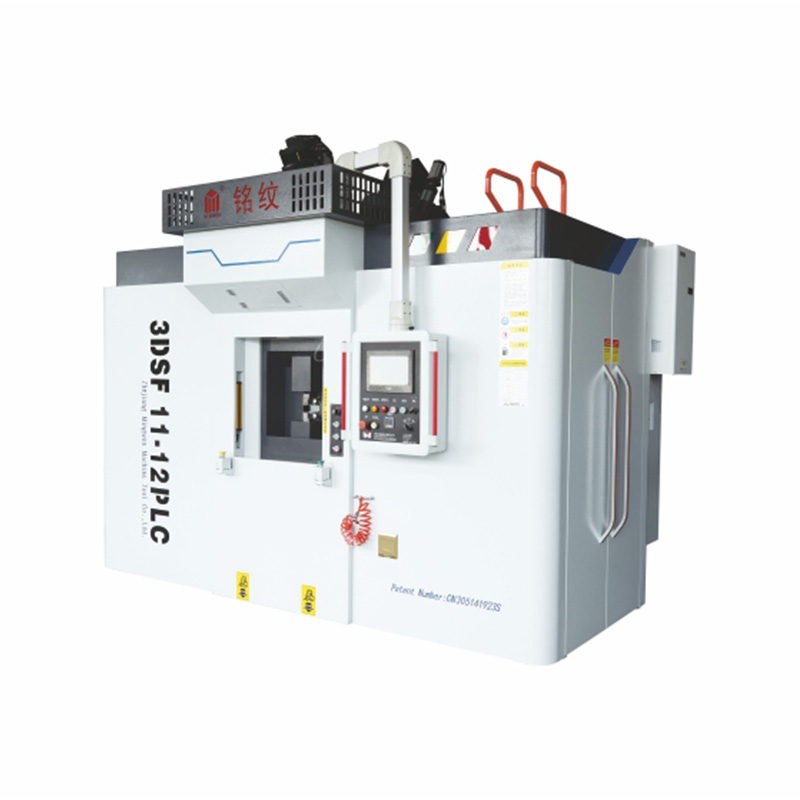

3DSF11-12PLC Automatic Rotary Transfer Machine For Joint

The 3DSF11-12PLC Automatic Rotary Transfer Machine For Joint is a solution designed to streamline the processing of tee-joints with unparalleled efficiency and precision. This innovative machine is engineered to handle the intricacies of joint manufacturing, offering a comprehensive suite of features that enhance productivity, reliability, and ease of operation.

Automated Loading and Unloading:

One of the standout features of the 3DSF11-12CNC is its fully automated loading and unloading capabilities. This significantly reduces manual intervention, to increased efficiency and a higher output rate. The machine is equipped with a sophisticated system that intelligently manages the loading and unloading process, ensuring seamless operation throughout the production cycle.

Modular Design for Versatility:

This rotary transfer machine boasts a modular design, allowing for versatile configurations to meet specific production requirements. The flexibility of the machine is enhanced by the ability to easily adapt to various tee-joint dimensions and specifications. This modular approach not only increases the adaptability of the machine but also facilitates quick changeovers between different production runs.

High-precision Machining:

The 3DSF11-12CNC is engineered for precision. It incorporates advanced machining technologies that deliver consistently accurate results, meeting the stringent tolerances required for tee-joint manufacturing. The machine's control systems ensure that each component is machined with precision, contributing to the overall quality and reliability of the end product.

Multi-axis Machining Capability:

Equipped with a multi-axis machining capability, this rotary transfer machine enables complex machining operations with a high degree of accuracy. The multiple axes allow for simultaneous machining of various features on the tee-joint, reducing cycle times and enhancing overall production efficiency. This feature is particularly beneficial for industries requiring intricate tee-joint designs.

Robust Construction for Longevity:

Built with durability in mind, the rotary transfer machine is constructed from high-quality materials that ensure longevity and stability during operation. The robust design contributes to the machine's ability to withstand the rigors of continuous manufacturing processes, providing a reliable and long-lasting solution for tee-joint production.

Customizable Tooling Options:

Recognizing the diversity of tee-joint requirements in different industries, this rotary transfer machine offers customizable tooling options. Users can tailor the tooling configuration to match specific project needs, ensuring good performance for a wide range of tee-joint geometries and materials. This adaptability contributes to the machine's versatility and makes it well-suited for diverse manufacturing applications.

Energy-efficient Operation:

In line with modern sustainability practices, the rotary transfer machine is designed for energy-efficient operation. The system is optimized to minimize energy consumption without compromising performance, contributing to both cost savings and a reduced environmental footprint.

Compliance with Industry Standards:

The 3DSF11-12PLC Automatic Rotary Transfer Machine For Joint adheres to stringent industry standards, ensuring that the manufactured tee-joints meet the required specifications. Compliance with these standards is essential for industries where product quality and consistency are paramount, providing peace of mind to manufacturers and end-users alike.

In conclusion, the 3DSF11-12PLC Automatic Rotary Transfer Machine For Joint stands out as a reliable and efficient solution for tee-joint manufacturing. Its combination of automated features, precision machining capabilities, modular design, user-friendly interface, robust construction, efficient chip management, energy-efficient operation, real-time monitoring, and compliance with industry standards make it a choice for businesses seeking a solution for joint processing.

About

Zhejiang Mingwen Intelligent Technology Co., Ltd.

Zhejiang Mingwen Intelligent Technology Co., Ltd. is a 3DSF11-12PLC Automatic Rotary Transfer Machine For Joint company and wholesale 3DSF11-12PLC Automatic Rotary Transfer Machine For Joint supplier specializing in the manufacture of special waterwheel valve machines.

The company specializes in designing and manufacturing a series of products such as waterwheel type, horizontal type, vertical type, turntable type linkage, and special gate valve sealing surface machines. At the same time, it can customize special machine tools, automated assembly lines, etc. according to user needs. "High precision, strong rigidity, low noise, durability, speed and efficiency" are the characteristics of Mingwen machine tool products.

News

-

Stable hydraulic pressure is crucial for achieving consistent performance in automated machining equipment. Many manufacturing environments ...

READ MORE -

Routine maintenance plays a major role in preserving the performance and reliability of any hydraulic machining system. This is especially t...

READ MORE -

In machining environments where high consistency and stable output are essential, hydraulic systems play a critical role in delivering smoot...

READ MORE -

Modern machining environments depend heavily on the consistent performance of hydraulic systems, especially when operating multi-station aut...

READ MORE

русский

русский Español

Español