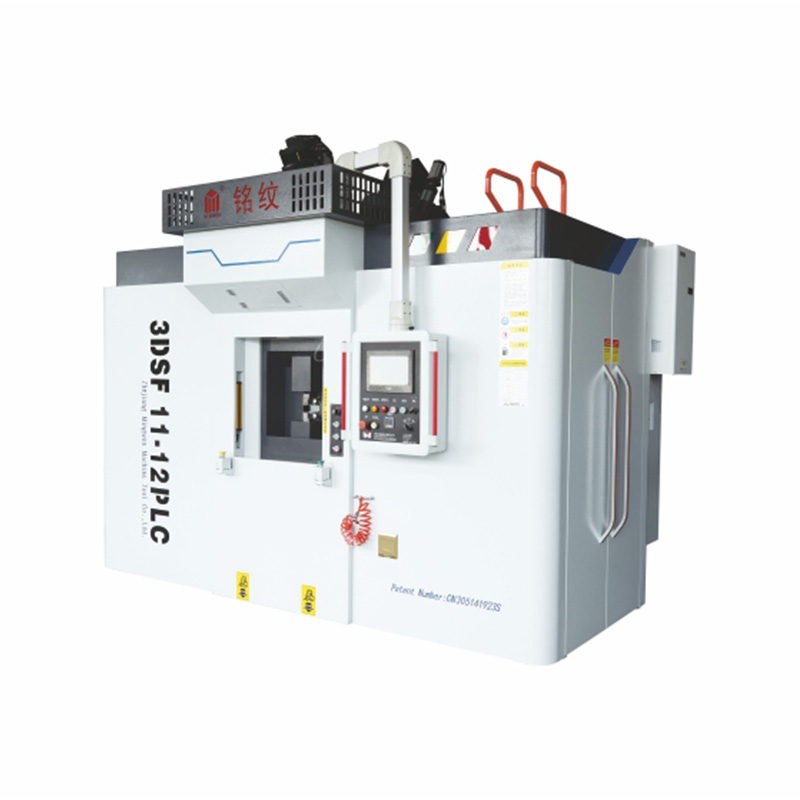

3DSF11-12PLC Rotary Transfer Machine For Female Angle Valve

The 3DSF11-12PLC Rotary Transfer Machine for Female Angle Valve represents a significant advancement in machining technology, designed to streamline the manufacturing process of 1/2 inch female angle valves. This advanced rotary transfer machine offers a range of features and capabilities that contribute to increased efficiency and precision in the production of these essential components.

Efficient One-Time Finish

One of the standout features of the 3DSF11-12PLC is its ability to achieve a one-time finish for the 1/2 inch female angle valve. This translates to a considerable reduction in processing time compared to traditional machining methods. The machine is engineered to perform all necessary operations in a single cycle, optimizing the production workflow and effectively reduce the need for manual intervention.

Precision Engineering

Precision is paramount in the manufacturing of angle valves, and the 3DSF11-12PLC excels in this regard. The machine incorporates advanced engineering principles to ensure accurate and consistent machining of each component. Tight tolerances are maintained throughout the production process, resulting in high-quality finished products that meet industry standards.

Versatile Machining Capabilities

This rotary transfer machine is equipped with a versatile set of machining capabilities, allowing it to handle a variety of tasks related to 1/2 inch female angle valves. From drilling and threading to surface finishing, the 3DSF11-12PLC can seamlessly execute multiple operations without compromising on precision or speed.

Automated PLC Control

The incorporation of Programmable Logic Controller (PLC) technology is a key feature that sets the 3DSF11-12PLC apart. The automated control system enhances the machine's efficiency by allowing for precise programming of machining sequences. This not only reduces the risk of human error but also facilitates easy adjustments to accommodate different production requirements.

Compact Footprint

Space efficiency is a crucial consideration in modern manufacturing facilities. The 3DSF11-12PLC is designed with a compact footprint, making it suitable for installations where space is limited. This thoughtful design allows manufacturers to optimize their floor space while still benefiting from the machine's advanced capabilities.

Robust Construction for Longevity

Durability is a fundamental characteristic of the 3DSF11-12PLC Rotary Transfer Machine. Constructed from high-quality materials and engineered to withstand the rigors of continuous operation, this machine is built to last. Its robust design ensures longevity, contributing to a reliable and cost-effective solution for manufacturers seeking equipment with a low total cost of ownership.

User-Friendly Interface

Operability is a key consideration in any machining equipment, and the 3DSF11-12PLC excels in providing a user-friendly interface. The machine's control panel is intuitively designed, enabling operators to easily program, monitor, and adjust machining parameters. This user-centric approach enhances overall productivity and reduces the learning curve for machine operators.

Ease of Maintenance

Maintenance is a critical aspect of ensuring the longevity and performance of any industrial equipment. The 3DSF11-12PLC is engineered with ease of maintenance in mind. Accessible components, clear documentation, and straightforward maintenance procedures make it simple for technicians to perform routine upkeep, minimizing downtime and the machine's availability.

In summary, the 3DSF11-12PLC Rotary Transfer Machine for Female Angle Valve is a solution for manufacturers seeking precision, efficiency, and reliability in the production of 1/2 female angle valves. With its advanced features, user-friendly interface, and commitment to quality, this machine stands as a practical choice for enhancing manufacturing processes in the plumbing industry.

About

Zhejiang Mingwen Intelligent Technology Co., Ltd.

Zhejiang Mingwen Intelligent Technology Co., Ltd. is a 3DSF11-12PLC Rotary Transfer Machine For Female Angle Valve company and wholesale 3DSF11-12PLC Rotary Transfer Machine For Female Angle Valve supplier specializing in the manufacture of special waterwheel valve machines.

The company specializes in designing and manufacturing a series of products such as waterwheel type, horizontal type, vertical type, turntable type linkage, and special gate valve sealing surface machines. At the same time, it can customize special machine tools, automated assembly lines, etc. according to user needs. "High precision, strong rigidity, low noise, durability, speed and efficiency" are the characteristics of Mingwen machine tool products.

News

-

Routine maintenance plays a major role in preserving the performance and reliability of any hydraulic machining system. This is especially t...

READ MORE -

In machining environments where high consistency and stable output are essential, hydraulic systems play a critical role in delivering smoot...

READ MORE -

Modern machining environments depend heavily on the consistent performance of hydraulic systems, especially when operating multi-station aut...

READ MORE -

A Rotary Transfer Machine Hydraulic is a robust production asset, yet its complex hydraulic system can develop issues that disrupt manufactu...

READ MORE

русский

русский Español

Español