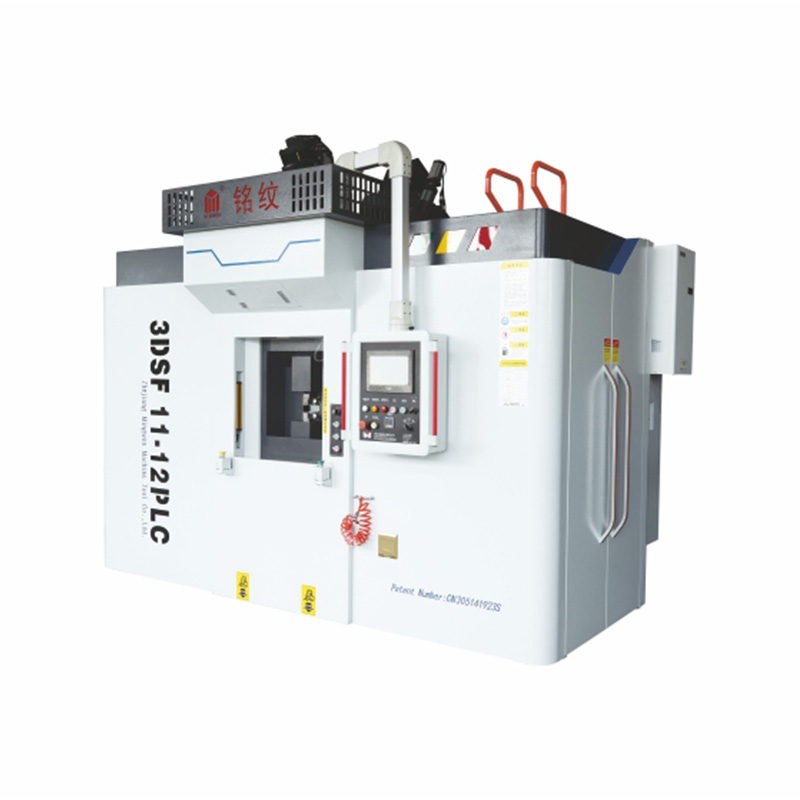

3DSF11-12CNC Servo Motor Rotary Transfer Machine For Safty Valve

In the realm of precision machining for safety valves, the 3DSF11-12CNC Servo Motor Rotary Transfer Machine emerges as a reliable and technologically advanced solution, catering to the intricate demands of safety valve manufacturing.

Technical Specifications:

CNC Servo Motor Control:

The 3DSF11-12CNC is equipped with advanced CNC servo motor control, providing high precision and flexibility in the machining process. The servo motors ensure smooth and accurate movements, contributing to the overall efficiency of the machine.

Rotary Transfer Mechanism:

Our machine incorporates a highly reliable rotary transfer mechanism, enabling one-time finishing of safety valve components. This innovative design effectively reduces production time and enhances the overall productivity of the manufacturing process.

Modular Design for Versatility:

The modular design of the 3DSF11-12CNC allows for easy customization and adaptation to varying production requirements. This versatility ensures that the machine can handle a diverse range of safety valve specifications, catering to the evolving needs of our clients.

Advanced Machining Capabilities:

With a focus on precision engineering, our machine boasts advanced machining capabilities, ensuring the production of safety valve components with tight tolerances. This attention to detail is essential for meeting industry standards and ensuring the reliability of the final product.

Key Advantages:

Efficiency Through One-Time Finishing:

The standout feature of the 3DSF11-12CNC is its ability to achieve one-time finishing of safety valve components. This not only accelerates the manufacturing process but also effectively reduces the need for additional processing steps, contributing to a more streamlined and cost-effective production workflow.

Precision and Consistency:

The integration of CNC servo motor control ensures precise and consistent machining of safety valve components. This level of accuracy is critical in industries where the reliability and performance of safety valves are paramount, such as in oil and gas, petrochemical, and manufacturing sectors.

Cost-Effective Modular Design:

Our machine's modular design is a key advantage, allowing manufacturers to adapt the system to specific production needs without the need for extensive retooling. This cost-effective approach enables businesses to optimize their investment and respond efficiently to changing market demands.

Reduced Downtime and Maintenance:

The reliability of the rotary transfer mechanism and other components contributes to minimal downtime and maintenance requirements. This operational robustness ensures that the 3DSF11-12CNC remains a dependable workhorse in your production facility, overall equipment effectiveness (OEE).

Adaptability to Varied Specifications:

The modular design and advanced machining capabilities empower the 3DSF11-12CNC to handle a wide range of safety valve specifications. This adaptability is crucial for manufacturers dealing with diverse product lines or catering to the specific requirements of different clients and industries.

Enhanced Operator Experience:

The user-friendly interface of the machine simplifies the operation, making it accessible to operators with varying levels of experience. This, in turn, reduces the likelihood of errors, enhances productivity, and contributes to a positive working environment.

In conclusion, the 3DSF11-12CNC Servo Motor Rotary Transfer Machine for Safety Valve represents a solution for manufacturers seeking precision, efficiency, and reliability in safety valve production. With its advanced features, this machine stands as a testament to our dedication to providing innovative and practical solutions for the evolving needs of the industry.

About

Zhejiang Mingwen Intelligent Technology Co., Ltd.

Zhejiang Mingwen Intelligent Technology Co., Ltd. is a 3DSF11-12CNC Servo Motor Rotary Transfer Machine For Safty Valve company and wholesale 3DSF11-12CNC Servo Motor Rotary Transfer Machine For Safty Valve supplier specializing in the manufacture of special waterwheel valve machines.

The company specializes in designing and manufacturing a series of products such as waterwheel type, horizontal type, vertical type, turntable type linkage, and special gate valve sealing surface machines. At the same time, it can customize special machine tools, automated assembly lines, etc. according to user needs. "High precision, strong rigidity, low noise, durability, speed and efficiency" are the characteristics of Mingwen machine tool products.

News

-

Modern machining environments depend heavily on the consistent performance of hydraulic systems, especially when operating multi-station aut...

READ MORE -

A Rotary Transfer Machine Hydraulic is a robust production asset, yet its complex hydraulic system can develop issues that disrupt manufactu...

READ MORE -

Balancing Advanced Capabilities with Operational Accessibility The value of an automated system is fully realized only when it can be operat...

READ MORE -

Adapting to Diverse Production Requirements A Rotary Transfer Machine Servo offers a flexible machining solution that combines rotation-base...

READ MORE

русский

русский Español

Español