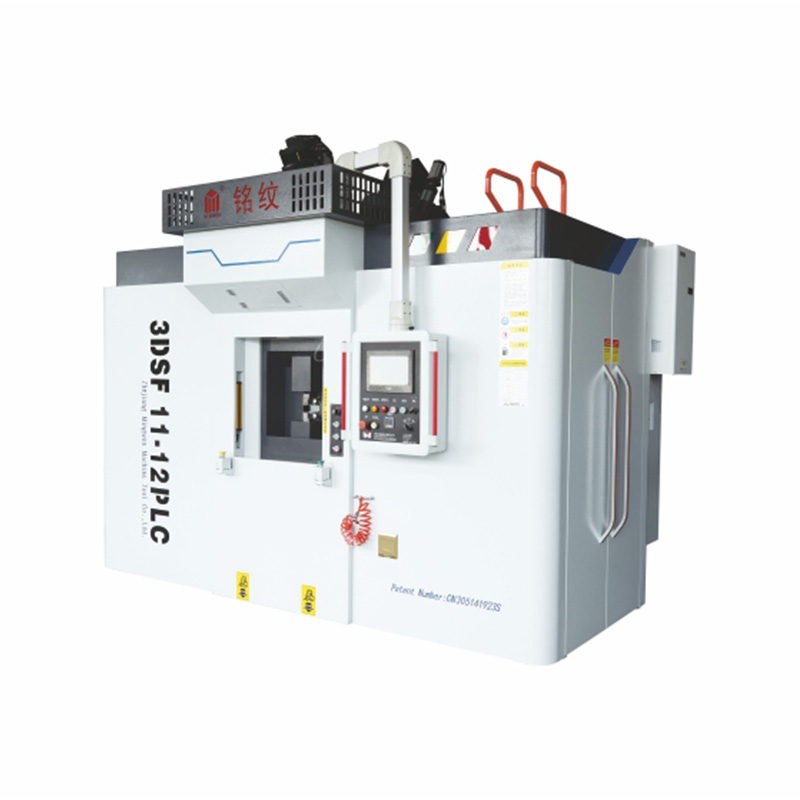

SL340 Inclined Bed Turning Cutting Drilling Metal CNC Lathe Machine

The SL340 Inclined Bed Turning Cutting Drilling Metal CNC Lathe Machine is designed to deliver precision and efficiency for metalworking tasks. Built on a high-quality, heavy cast iron bed, this machine provides a solid and durable foundation that ensures long-term reliability. The bed undergoes heat treatment and annealing processes, enhancing its strength and stability. This rigorous construction approach helps the machine maintain accuracy and performance even under demanding operational conditions.

The 35-degree slant bed design is a key feature of the SL340. This single-piece structure not only contributes to the machine's rigidity but also allows it to withstand heavy cutting forces. The slant bed design plays a critical role in maintaining consistent precision during machining, making it an ideal choice for producing high-precision parts. Additionally, this inclined design offers practical benefits such as easier operator access to the work area and more efficient chip removal, which is essential for maintaining a clean and safe working environment.

Advantages of the SL340

The SL340's robust cast iron base is a defining characteristic that sets it apart. By being heat treated and annealed, the base provides the necessary foundation for high-speed and highly accurate machining operations. This process ensures that the machine can handle the stresses of continuous operation without compromising on the quality of the finished products.

One of the significant advantages of the slant bed design is its contribution to the machine's overall rigidity. The 35-degree inclination enhances the machine's ability to withstand heavy cutting forces, which is crucial for achieving precise machining results. This design also simplifies the operator's tasks, allowing for more straightforward access to the workpiece and facilitating efficient chip evacuation. These features combine to create a machine that not only performs well but also enhances productivity in the workshop.

In terms of value, the SL340 offers a competitive option for those seeking a high-quality machine capable of handling high-volume production. The combination of a rigid bed, advanced tooling options, and efficient chip management ensures that this lathe can deliver accurate parts consistently and at a lower cost per unit. The integration of rapid X/Z axis speeds and a gang tool setup further boosts productivity, making the SL340 an asset in any metalworking operation.

Standard Features

The SL340 comes equipped with several standard features that enhance its functionality and ease of use. These include hydraulic collets, which provide secure and reliable workpiece clamping, and gang type tooling, which allows for quick and efficient tool changes. The ergonomic operator panel design ensures that the machine is user-friendly, reducing operator fatigue and improving overall efficiency. Additionally, the SL340 is equipped with an automatic lubrication system that maintains the machine’s moving parts, ensuring smooth operation and reducing the need for frequent maintenance. The automatic coolant system helps manage the heat generated during machining, protecting both the workpiece and the tooling from excessive wear. Built-in safety features ensure that the machine operates safely, less the risk of accidents in the workshop.

Optional Features

To further tailor the SL340 to specific operational needs, a range of optional features is available. Different chucks and collets can be selected to accommodate various workpiece sizes and shapes, offering greater versatility in machining operations. Updated control systems can be integrated to enhance the machine's functionality and ease of use, allowing for more complex machining processes and better overall control. The option for live tooling expands the machine's capabilities, enabling more intricate operations without the need for additional equipment. Additionally, a bar feed option is available, which is particularly useful for high-volume production environments, as it allows for continuous machining without manual intervention.

The SL340 Inclined Bed Turning Cutting Drilling Metal CNC Lathe Machine is a versatile and reliable choice for metalworking tasks. With its solid cast iron base, advanced design features, and range of standard and optional features, it is well-suited to meet the demands of precision machining in various industrial applications. Whether used for high-volume production or complex part fabrication, the SL340 delivers consistent performance, making it a valuable addition to any workshop. Its combination of durability, efficiency, and flexibility ensures that it can handle a wide range of machining challenges, providing quality results with every use.

-

Routine maintenance plays a major role in preserving the performance and reliability of any hydraulic machining system. This is especially t...

READ MORE -

In machining environments where high consistency and stable output are essential, hydraulic systems play a critical role in delivering smoot...

READ MORE -

Modern machining environments depend heavily on the consistent performance of hydraulic systems, especially when operating multi-station aut...

READ MORE -

A Rotary Transfer Machine Hydraulic is a robust production asset, yet its complex hydraulic system can develop issues that disrupt manufactu...

READ MORE

русский

русский Español

Español